The future's bright: Shining a light on advanced technology

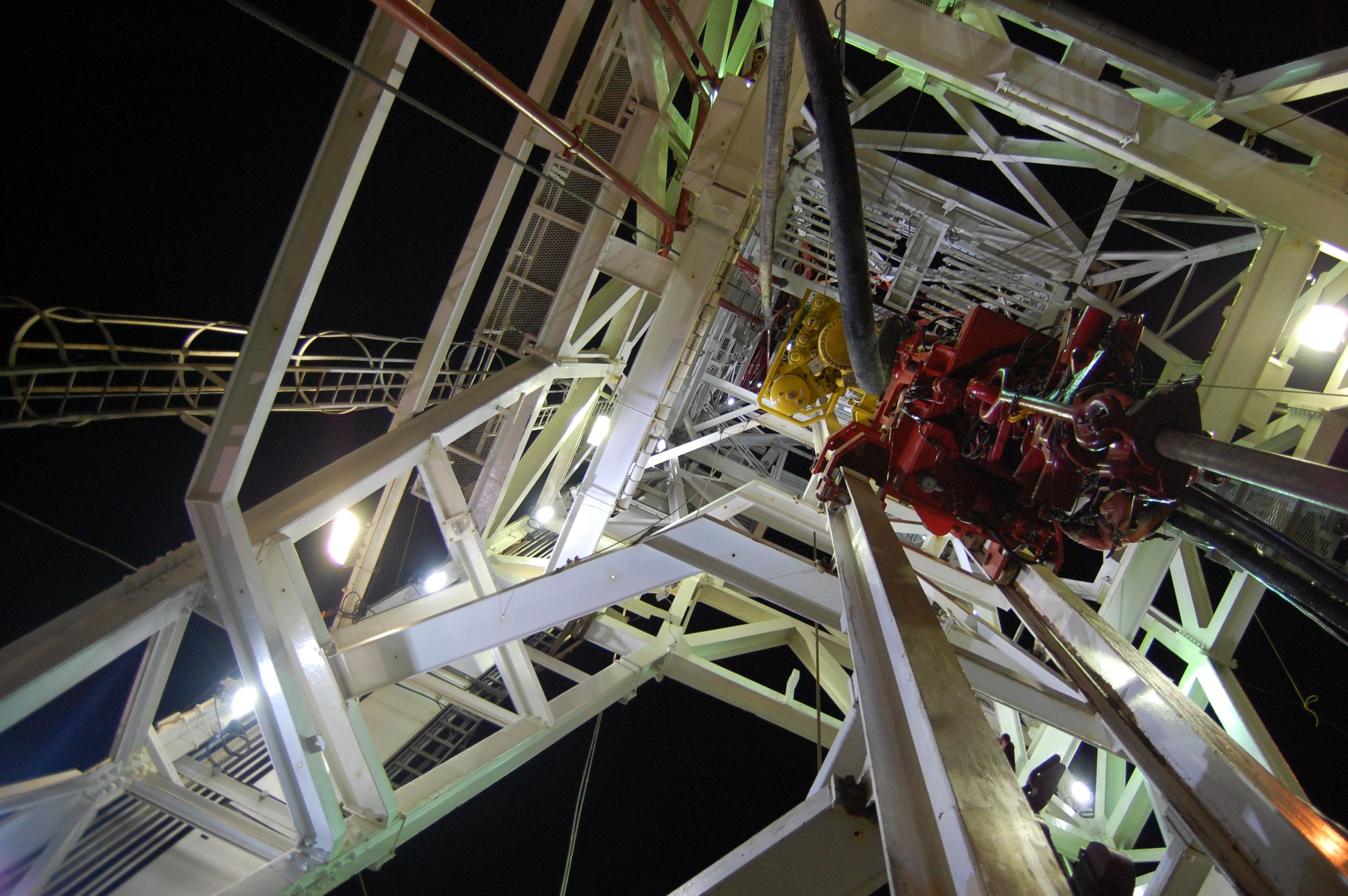

Explosion proof LED lighting can secure significant efficiencies offshore while supporting the transition to a carbon-neutral industry.

The Challenge

Investigating the adoption of LED lighting on multiple offshore installations for a major North Sea operator.

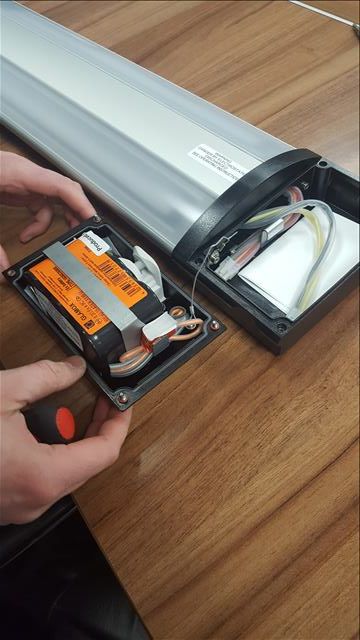

The client was looking to replace old fluorescent and gas-based products used for general and emergency lighting.

One of the key drivers of the exercise was to accelerate the move towards net-zero carbon targets.

The Response

Dron & Dickson professionals conducted a technical review of the old fluorescent technology and the LED alternative, to qualify and quantify the benefits of an upgrade.

The review, focused on areas such as maintenance, inspection and recycling, was designed to understand the return-on-investment (ROI) and energy efficiency outcomes as well as the sustainability gains.

The process drew upon Dron & Dickson’s internal data on:

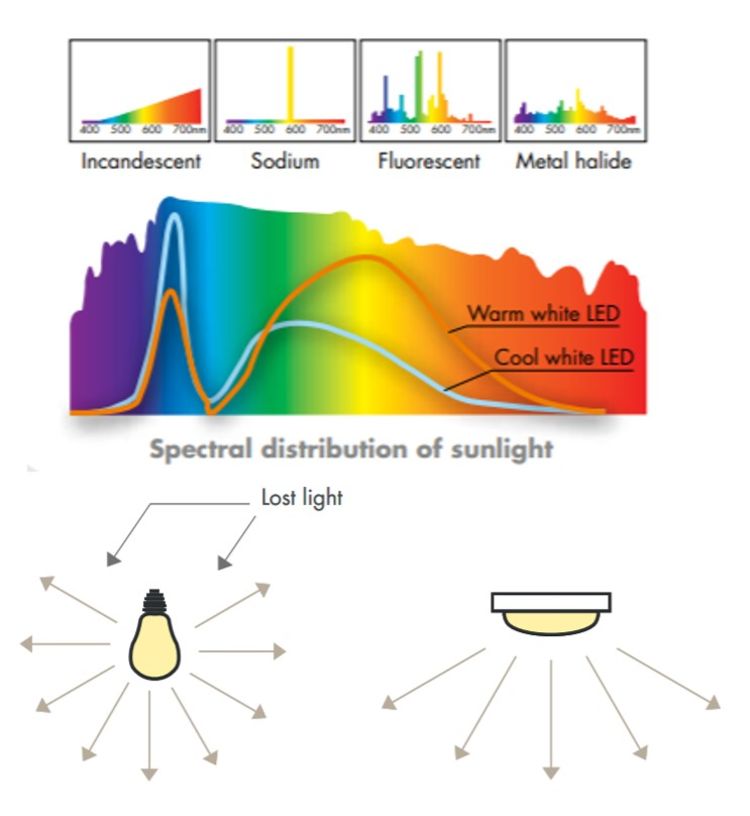

· energy consumption and efficiency

· installation, inspection and maintenance time

· commercial ROI, light output and safety compliance

The Result

A detailed evaluation pinpointed a 40% reduction in energy consumption by adoption of the LED solution.

The review also identified:

· a 46% reduction in inspection time – yielding significant savings when multiplied by several thousand fittings per asset

· a decrease in regular maintenance costs due to the selection of a sealed fitting solution

· major savings in the annual spend on maintenance spares and fittings replacements

· a cut in storage costs thanks to the 60% reduction in the volume of stocked spare parts

· a reduction in the recycling of hazardous mercury-based tubes

· enhanced lighting performance – delivering more efficient output and supporting improved safety during task execution

Overall, the review by Dron & Dickson – the largest supplier of explosion-proof LED lighting in the UK oil & gas sector – conservatively assessed the ROI at under six years, with even greater savings thereafter.

‘…a 40% reduction in energy consumption… a 46% reduction in inspection time… major savings in the annual spend on maintenance spares…’

Find out more: www.drondickson.com

Contact: tom.irwin@drondickson.co.uk

Explore our Case Studies Gallery