Sulfur recovery: Using data to deliver optimum results

A self-service approach to monitoring is applied to help improve capture rates and enhance environmental performance.

The Challenge

Identifying – and resolving – issues associated with sulfur recovery in refineries and gas plants.

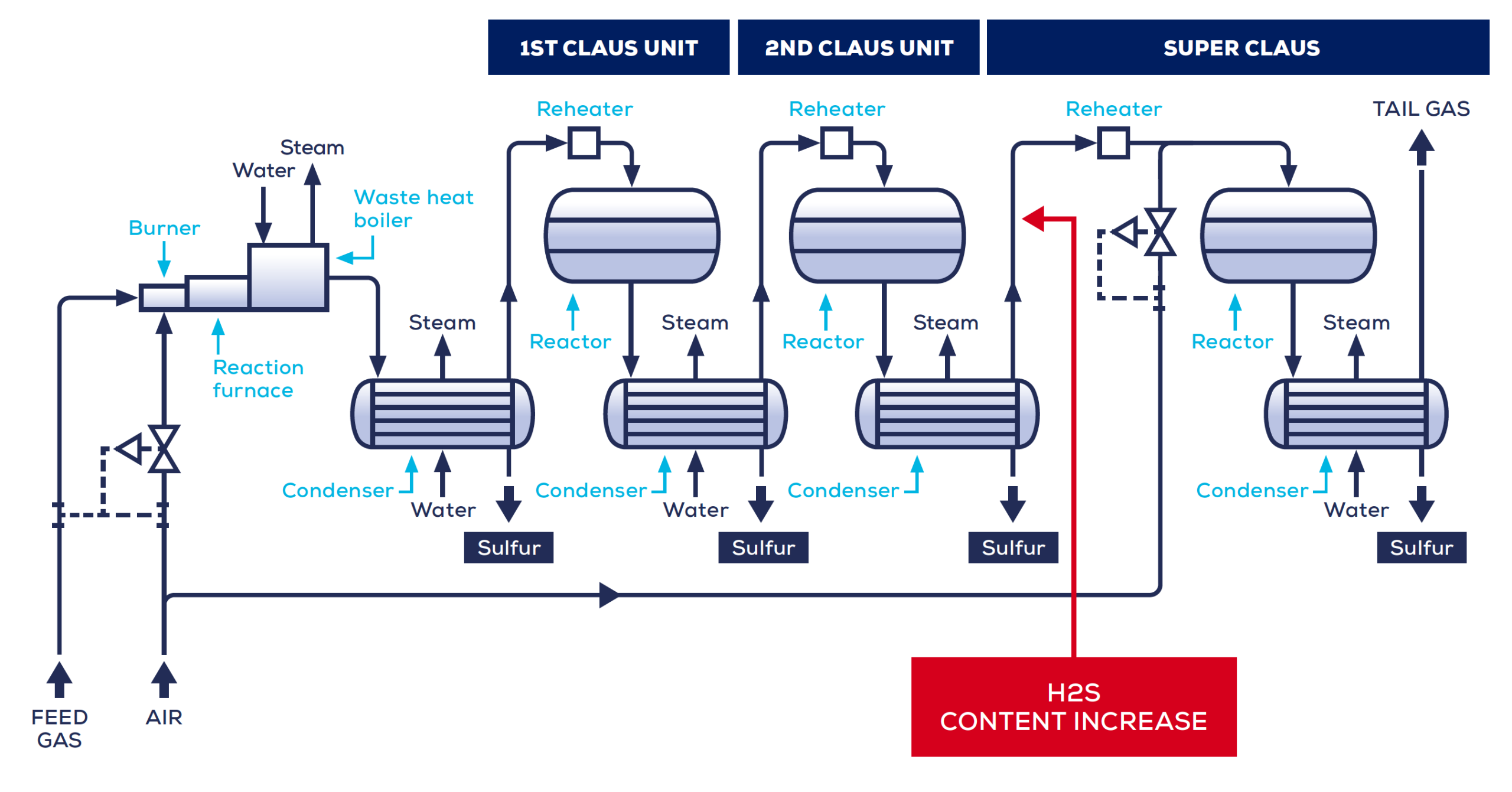

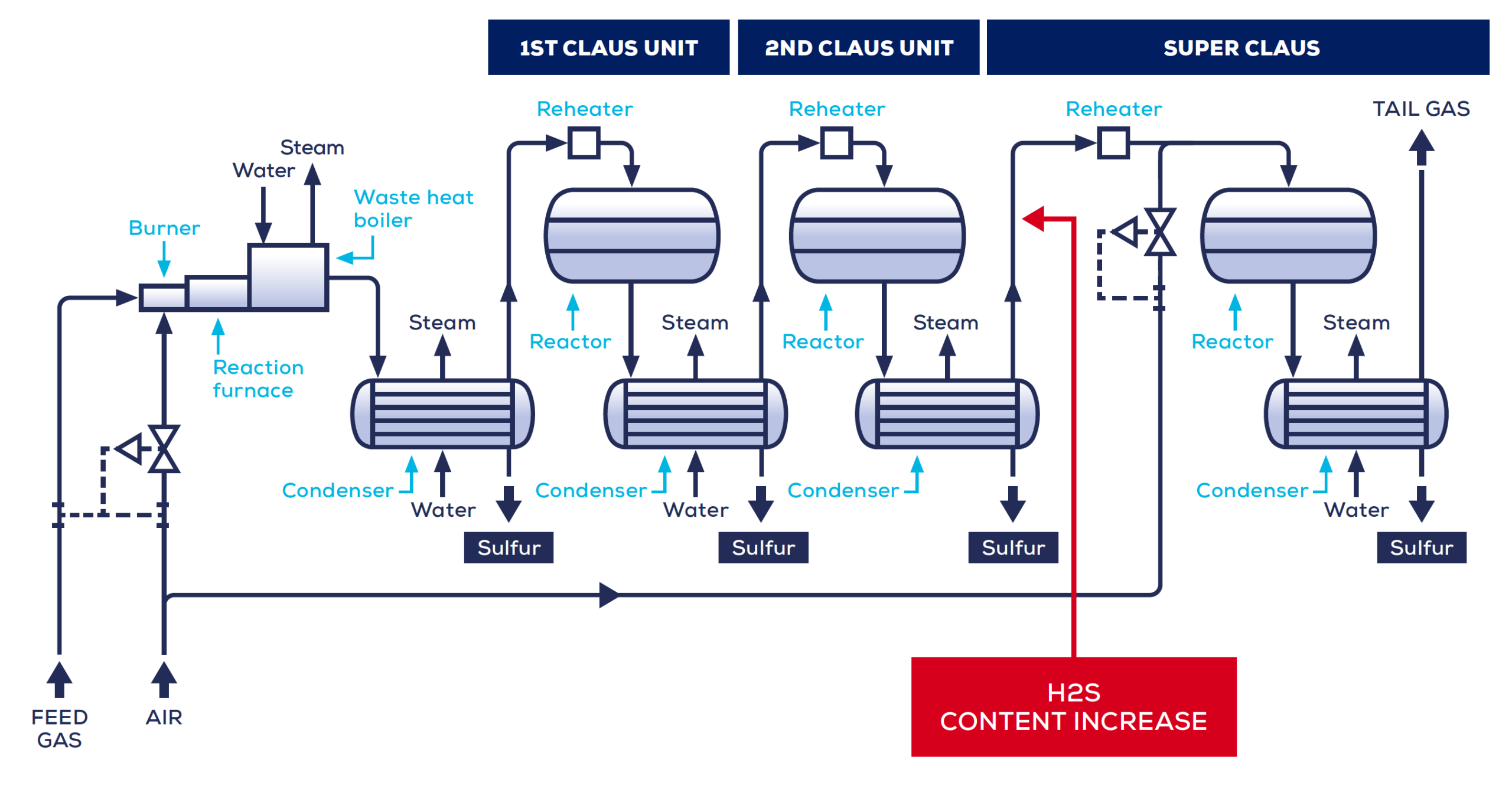

Sulfur recovery units (SRUs) are used to capture sulfur, reduce emissions and ensure compliance for operators.

Encompassing a series of technical processes, they are becoming ever more important due to the rising demand for sulfur in various applications and the regulatory obligations around emissions control.

Conventional means of monitoring the operational performance of SRUs and assessing the scale of any issues as they arise involve time-consuming, multidisciplinary data analysis projects.

The Response

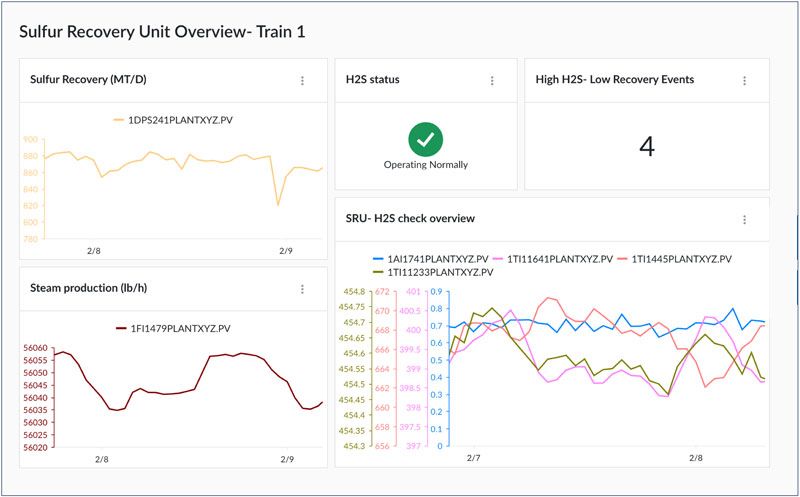

TrendMiner has introduced a ‘production cockpit’ concept which can be applied to monitor for when – for any of a variety of potential technical reasons – the non-converted Hydrogen Sulfide in the process is higher than expected, signalling a decrease in sulfur recovery rates.

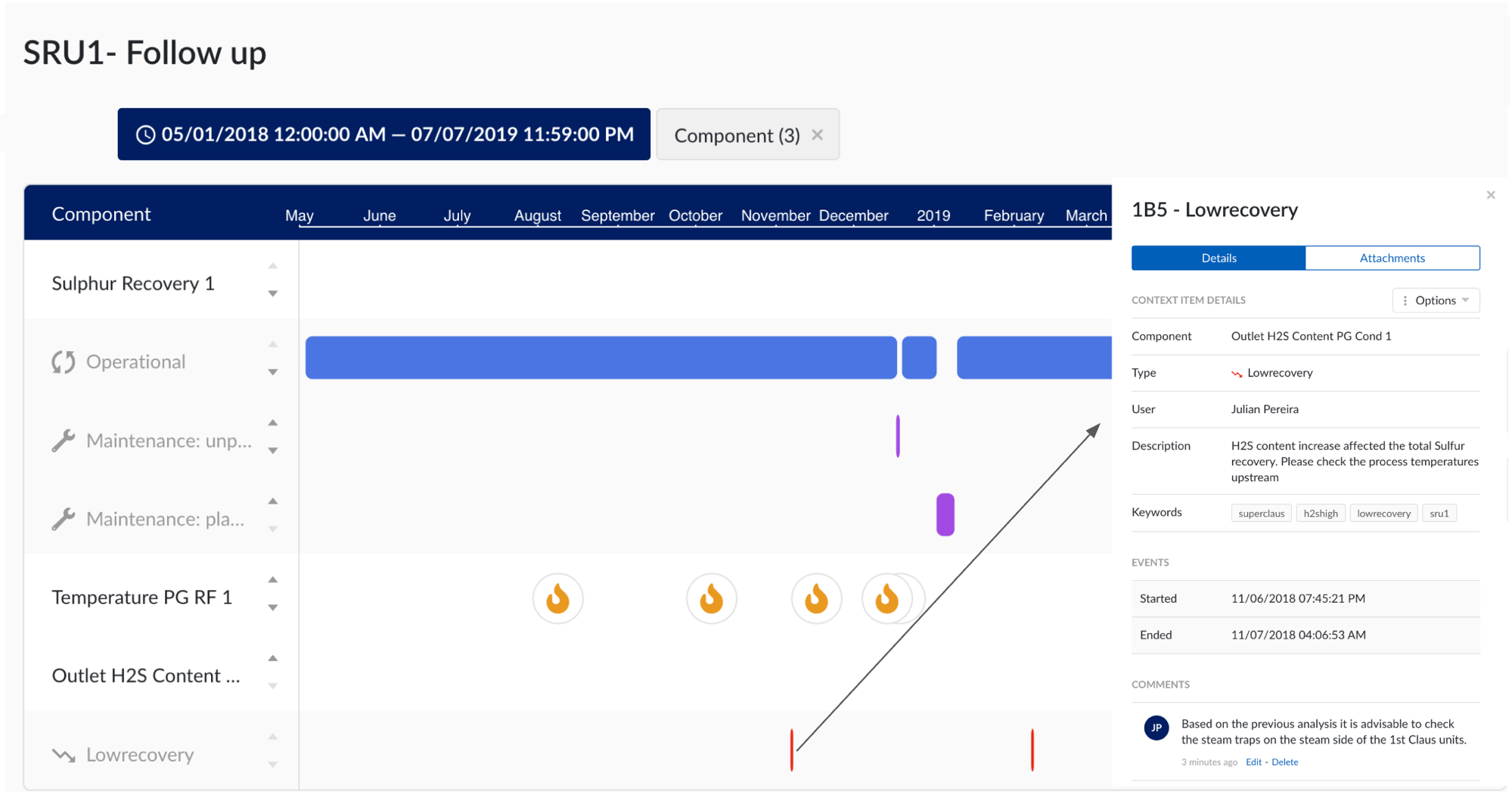

Process engineers can use self-service analytics tools, which eliminate the need for complex excel sheets or long data modelling projects that are less suited for process-related optimisation projects.

These tools are applied to visualise and monitor the process, assess the size of the problem, drill down to a series of root causes and facilitate measures to prevent a recurrence.

It equips process engineers to perform all data analytics themselves, including the use of contextual data from other business applications.

The Result

The solution facilitates the fast delivery of key data directly into the hands of process engineers who can assign meaningful interpretations to the data.

In one instance, the process of finding the root causes associated with an underperforming SRU train – then making the necessary changes and introducing proactive monitoring – produced highly positive results. Train performance was even better than before the data analysis work, resulting in 8% higher unit utilisation, an increase in sulfur recovery from 96.5% to 99.3% and a 15% reduction in SO2 emissions.

In principle, this strategic approach of putting advanced analytics in the hands of subject matter experts allows them to handle 80% of energy-related cases that contribute to corporate goals for reducing the carbon footprint.

For clients, this approach means:

· uncovering insights at all levels of production and thereby improving day-to-day decision making

· extracting maximum value from the large data sets generated from a variety of sensors, instruments and assets

· improving process workflows and realising more efficient emissions control and reduction.

‘Train performance was even better than before the data analysis work, resulting in 8% higher unit utilisation, an increase in sulfur recovery from 96.5% to 99.3% and a 15% reduction in SO2 emissions’

Find out more here .

Contact: Julian Pereira, Head of Customer Success EMEA julian.pereira@trendminer.com

Explore our Case Studies Gallery