MONITORING SOLUTION PRODUCES THE GOODS

A smart monitoring system that serves to pinpoint the causes behind the contamination of produced water offshore – and expedite the remedial process – has demonstrated how it can deliver multi-million-dollar savings and underpin regulatory compliance.

The Challenge

Quickly and efficiently identifying the reasons for high oil-in-water concentration and minimising production losses.

Produced water disposal is one of many challenges at oil and gas facilities with high water-cut wells. Keeping the oil contamination level in produced water below environmental limits requires an efficient separation process, which is governed by a series of complex physical interactions.

Significant production losses are associated with high oil-in-water level scenarios, because safely discharging water to the sea requires slowing down production while troubleshooting for the source of the issue.

To identify what could be causing high oil-in-water concentration, operators often take spot sample measurements at different parts of the production facility and then perform mitigating actions.

Working with the industrial software provider Cognite, the independent oil and gas operator Aker BP saw the opportunity to develop more accurate techniques to locate the source of contamination more efficiently.

The Response

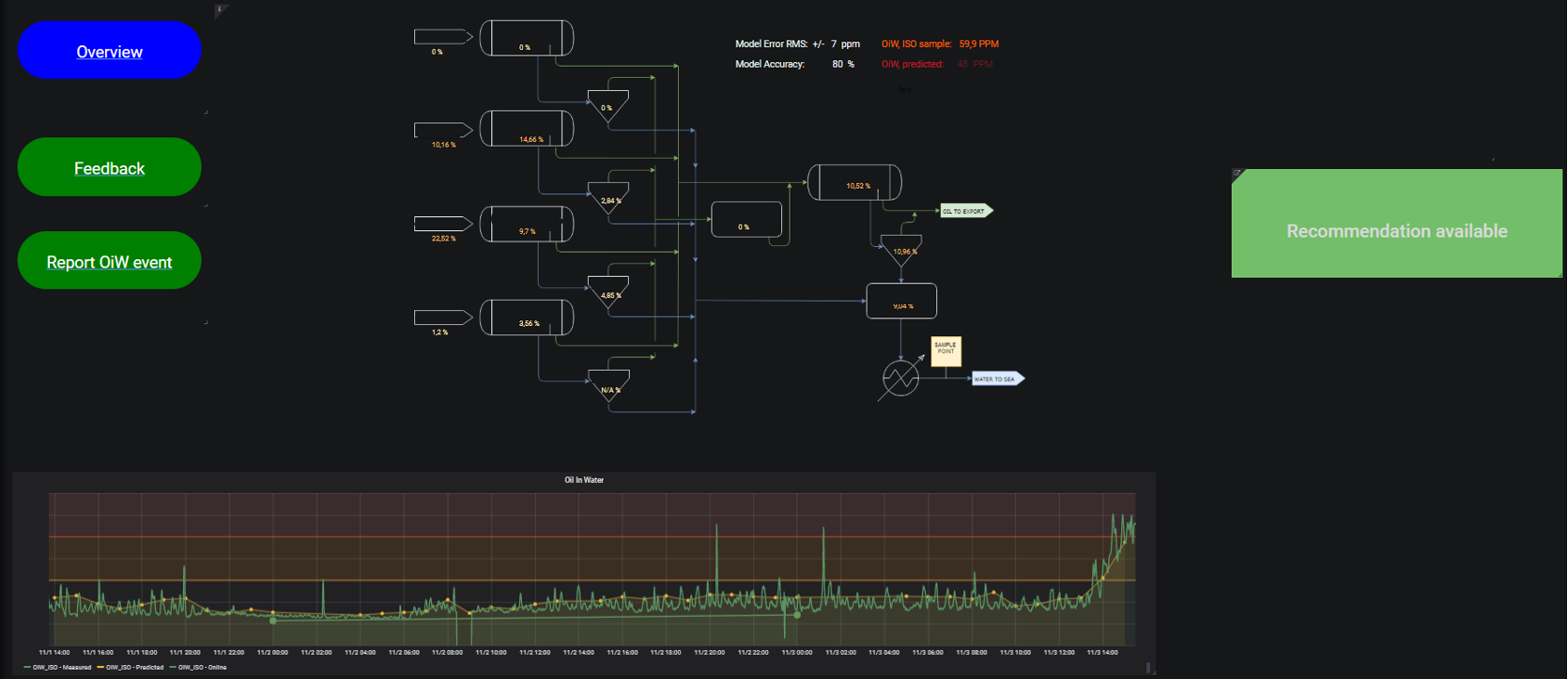

Aker BP and Cognite have implemented a smart monitoring system that visualises all data relevant for troubleshooting water contamination and a machine-learning powered solution that helps operators identify the source of high oil-in-water concentrations by recommending where they should begin troubleshooting.

The smart monitoring systems features a dashboard that provides engineers with calculations that combine virtual sensor values and simulator outputs—information that they would not otherwise have readily available. The machine learning-powered solution is fed with data from the Industrial DataOps platform Cognite Data Fusion. The machine model is trained to predict oil-in-water concentrations based on historical data from approximately 200 physical sensors from production wells and equipment relevant to produced water.

In addition to physical sensor values, the model is also fed values from approximately 100 virtual sensors. To cite one example: data from pressure and temperature sensors is converted to fluid properties by applying the laws of thermodynamics and information about the fluid composition.

Finally, the model also considers virtual sensor values obtained from multiphase flow simulators such as flow rates from individual wells.

Finally, the model rates each parameter or property in the production facility in terms of how likely they are to be the cause of the high oil-in-water concentration. Operators can then review this information to begin troubleshooting and resolve the issue.

The Result

The system was deployed to help Aker BP comply with regulations on oil-in-water and reduce production losses.

Aker BP estimates that decreasing the time spent finding mitigating actions has an annual revenue potential of $6 million. The system could also have a net positive environmental impact.

In summary, the smart monitoring system gives engineers the ability to troubleshoot issues related to water contamination in a single dashboard, increasing their situational awareness. This allows users to take informed actions based on the available data and solve problems faster. When the proposed recommender system is in place, it becomes an integral part of the monitoring system that will highlight which parts of the production facilities may be important for monitoring current oil-in-water concentration.

This serves as a starting point for investigating the problem, and is a significantly faster approach to identifying mitigating actions related to water contamination.

Key outcomes:

● $6 million in estimated annual savings and reduced production losses

● reduces time needed to identify causes behind high oil-in-water levels

● secures regulatory compliance and prevents environmental incidents.

‘… allows users to take informed actions based on the available date and solve problems faster.’

Find out more: www.cognite.com

Contact: Sarah Robertson sarah.robertson@cognite.com

Cognite is a global industrial SaaS company that supports the full-scale digital transformation of asset-heavy industries around the world.

Explore our Case Studies Gallery