IT’S GOOD TO SHARE: ARTIFICIAL INTELLIGENCE SOLUTIONS DELIVER VERY REAL INVENTORY SAVINGS

Artificial Intelligence and cloud technologies

can transform inventory management performance

– and in the process secure operational, safety and carbon footprint benefits.

The Challenge:

The oil & gas inbound supply chain is synonymous with large warehouses full of slow-moving inventory which often lies untouched for years. It’s a fact that more than half of most industry inventory moves less than once every four years – that’s a turnover of less than 0.25.

In the UK alone, billions of pounds’ worth of slow-moving inventory sits idle: gathering dust, losing value and waiting to be issued against a maintenance work order. Eventually, at the end of the asset’s life, this inventory will be gathered en masse and scrapped or sold at a fraction of the original purchase price.

It’s not just the cost of the inventory that needs to be considered: it’s also the cost of maintaining it, the investment in suitable storage facilities and the carbon footprint which it creates from manufacture to disposal.

The Response:

This challenge has been addressed by DIGATEX using Artificial Intelligence and cloud technology. DIGATEX enables inventory sharing to reduce and rationalise inventory within a single asset by de-duplicating spares and rationalising bills of materials (BoMs) within multiple BUs and across operators. It also does so by pooling inventory and speeding up and sharing the flow of data across the whole supply chain – from suppliers to logistics to engineering companies to operators.

In terms of the net zero agenda, DIGATEX supports carbon footprint reduction objectives by enabling the sharing of inventory across the resource sector, reducing storage requirements (fewer duplicate items), reducing the manufacturing of new items (by sharing what is already in place) and ensuring up time (making supply chain visible across the sector) while cutting operating costs (by disposing of unwanted materials/equipment). This all facilitates rationalisation of the resource sector as it transitions to greener energy provision.

The inventory sharing project is global, with hubs in existence in UK and Australia and others to follow. It is summarised as ‘creating a greener environment through sharing of inventory in the resource sector and into new energy areas’.

‘DIGATEX are focussed on reducing the carbon footprint of our current assets as they transition to a greener environment by enabling maximum use of materials and equipment already manufactured while maintaining asset integrity and up time”

The Result:

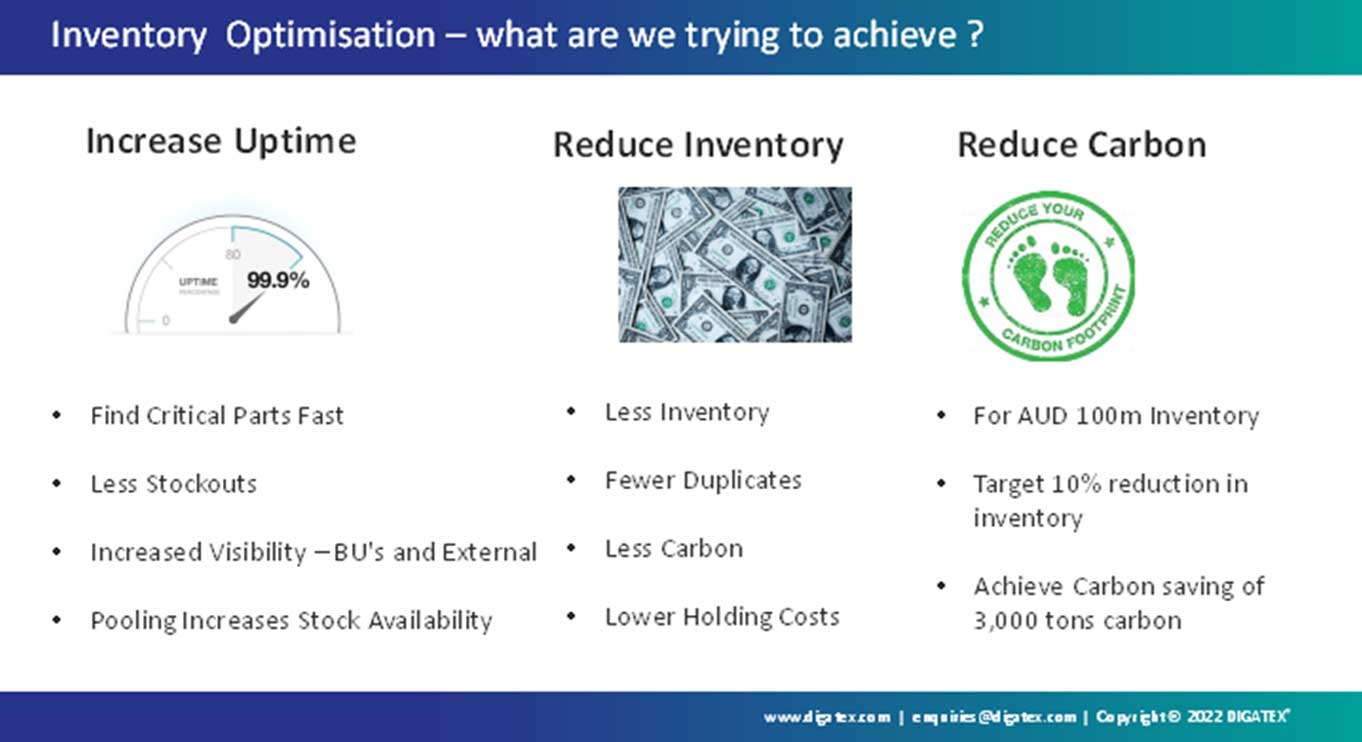

To cite one cost saving and carbon reduction scenario:

Large operators have approximately $100m of inventory stored, with a target saving of 10% – or $10m – per site. If it is assumed, conservatively, that there are 3,000 upstream assets globally participating in an inventory share programme, the total inventory available is $300bn. A 10% saving will yield a collective gain of $30bn.

The car industry, which has researched the issue in the context of carbons savings, offers a useful insight into the potential benefits if those savings are converted to carbon. The research indicates that the manufacture of an average family car involves 15 tons of carbon. If we assume an average car costs $50k, the total carbon saving against the 10% saving target is equivalent to the manufacture of 6,000 cars – an overall carbon footprint dividend of 9bn tons.

Inventory Hub in action

A UK operator purchased equipment for a turnaround, but discovered that the equipment was not suitable. Through the DIGATEX Inventory Hub, it found that an operator in Australia had an equivalent piece of equipment which complied with the specification. The equipment was shipped to the UK, averting the cancellation/postponement of the turnaround and delivering associated savings.

Find out more: www.digatex.com

Contact: Richard.beck@digatex.com

Explore our Case Studies Gallery